custom cast steering wheel for boat

Product Description

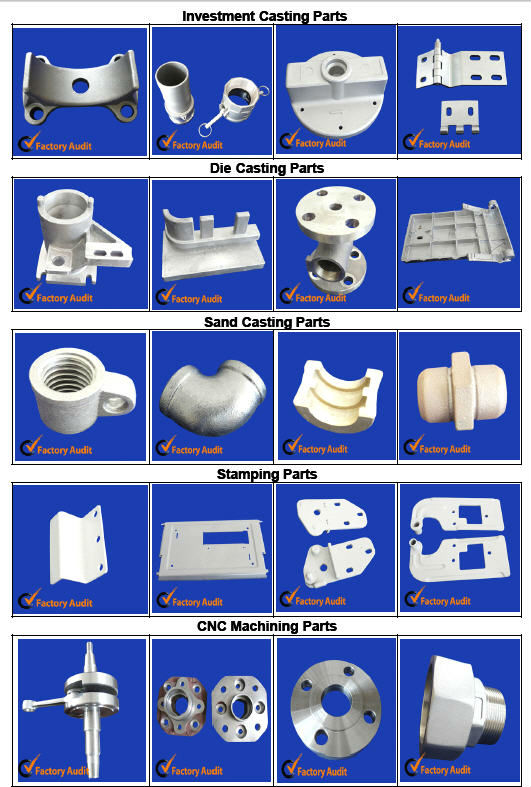

Product Description OEM and customized service • Quality guarantee • Chemical checking • NDE after rough machining • Mechanical testing after heat treatment • Final NDE,dimension inspected CASTING PROCESS:

Product Description OEM and customized service • Quality guarantee • Chemical checking • NDE after rough machining • Mechanical testing after heat treatment • Final NDE,dimension inspected CASTING PROCESS: | Casting process | Material |

| Investment casting | ASTMA148class80-40, ASTMA148Class80-50 A572GR60, AISI316 stainless steel, ST52, S355, GS-52.3, ASTMA48Class30B CK45, 1.7218-25CrMo4 |

| Sand casting | GGG50,GGG30, ASTMA48 class25B, 42CrMo4, C22 ductile iron 65-45-12, AlCuMgpbF34, EN-JIS-500-7 EN1563 , EN10293-GE300 HT200, DIN17205-GS-25CrMo4 |

| Die casting | C1040, A356, A380 AISI12 |

| Process | Suitable Material | |

| Sand Casting | Green Sand |

Grey Iron, Ductile Iron, Malleable Iron, Stainless Steel, Carbon Steel, Aluminium,Copper, Brass,Bronze

|

| Furan Resin Sand | ||

Cold Harden Resin Sand | ||

| Investment Casting | Soluble glass casting (Water Glass casting) | Stainless Steel, Carbon steel, Low Alloy Steel, Brass,Brone, Aluminium |

Silica Sol casting | ||

| Lost-foam casting | ||

| Combining silica sol casting process with soluble glass casting | ||

| Forging,Powder metallurgy | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Steel,Brass, Aluminium |

| Die Forging | ||

| Roll Forging | ||

| Stamping | All Metal Material | |

| Machining | All Metal Material | |

| Die casting | Aluminum alloy,zinc | |

Packaging & Shipping 1. plastic bags inside 2. wooden cartons 3. pallet or as customers' requirement Generally we choose the 20 container for the product of the largest weight . we are promised that we will make the best package for the product at the reasonable price.

Packaging & Shipping 1. plastic bags inside 2. wooden cartons 3. pallet or as customers' requirement Generally we choose the 20 container for the product of the largest weight . we are promised that we will make the best package for the product at the reasonable price.  Customer Visit

Customer Visit

FAQ 1 . How to contact with your company? Please send email to us tll"@qdtll.CN" 2 .What does your company need to submit a quotation? Drawing or sample, together with relevant information, such as quantity, weight, material. 3. Which kind of format of the drawing? PDF, IGS, DWG, STEP, etc 4 . What if we do not have a drawing? We can duplicate your sample and make drawing for your confirmation. 5. How soon before I get a sample? weeks for mold and sample, 3-7 days for express. 7.Where does your company locate? Qingdao, China, which is famous of Qingdao Beer and Metal Parts. 8.Can I visit your company? Yes, sure, welcome your visit anytime. We will book hotel and pick you up from airport. 9. How can we quote for you? As our factory only supply OEM service(custom service) Please send us enquiry by email, with all the technical drawings you have, with all of your requirements, such as material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less. It is also best if you can provide a sample, we can also quote depends on the sample. Home

FAQ 1 . How to contact with your company? Please send email to us tll"@qdtll.CN" 2 .What does your company need to submit a quotation? Drawing or sample, together with relevant information, such as quantity, weight, material. 3. Which kind of format of the drawing? PDF, IGS, DWG, STEP, etc 4 . What if we do not have a drawing? We can duplicate your sample and make drawing for your confirmation. 5. How soon before I get a sample? weeks for mold and sample, 3-7 days for express. 7.Where does your company locate? Qingdao, China, which is famous of Qingdao Beer and Metal Parts. 8.Can I visit your company? Yes, sure, welcome your visit anytime. We will book hotel and pick you up from airport. 9. How can we quote for you? As our factory only supply OEM service(custom service) Please send us enquiry by email, with all the technical drawings you have, with all of your requirements, such as material grade, tolerance, machining demands, surface treatment, heat treatment, mechanical property requirements, etc. Our specialized engineer will check and quote for you, we would appreciate the opportunity and will respond in 3-5 working days or less. It is also best if you can provide a sample, we can also quote depends on the sample. Home  Contact N

Contact N

Foundry and machining factory | . ISO 9001-2000 approved | |

2 | Casting experience | Over 15 years,OEM service available |

3 | Trade experience | Over 10 years |

4 | Strong enginnering team | Accurately read drawing,offer competitive price and gurantee good qualitly products |

5 | Our contracted customers | US, Canada, France, UK, Germany,Poland,Italy Denmark,Austria,Australia, Malaysia,singopore,Pakistan,brazil... |

6 | The whole casting procedure in sequence | pattern design, pattern making, casting, heat treatment, surface finish, and machining. |

7 | Production euipment | production line of investment casting introduced from Taiwan,spectrum analyzer device imported from Germany,vacuum melting furnace,CNC machine center |

8 | Test Euipment | spectrum analyzer, Physio-chemical Laboratory...

|

9 | Production lines | 1) The lost-wax casting of stainless steel and heat-resisting steel with silica-gel shell made of mid-temperature wax materials; 2) Two lines of lost-wax casting of carbon steel and alloy steel with water glass shell made of low-temperature wax material; 3) The resin sand casting of ductile iron and gray iron; 4) Non-ferrous casting with investment casting or sand casting process; 5) Advanced machining center. |

10 | Annual output | 500 tons of stainless steel and heat-resisting steel casting;1,000 tons of alloy steel and carbon steel casting; 50 tons non-ferrous casting, and 2,000 tons of gray iron and ductile iron casting. |

Product Categories : OEM Tools & Hardware > Marine Hardware

Premium Related Products